The workability of concrete is the consistency and ease with which freshly mixed concrete or mortar may be mixed, placed, compacted, and finished. In actuality, it’s the exact amount of labour that may be used for production within the company to get 100% compaction.

An additional term used to describe freshly formed concrete is consistency, which describes the ease with which it will flow. The concrete’s moisture content and its fluidity, or mobility, are the determining factors. Though workability may differ between concretes with the same viscosity, moist concretes are easier to work with than dry concrete. Certain tasks may not always be appropriate for concrete with higher consistency and more mobility. The kind of work, section thickness, reinforcements, and compaction technique are some of the considerations that must be considered while evaluating whether a certain job is feasible.

Factors Effecting workability of Concrete

With just the necessary amount of compacting effort, workable concrete overcomes frictional resistance and exhibits extremely little internal friction between particles. Concrete’s workability is dependent on many interconnected aspects. The variables influencing workability include cement fineness, additive application, water content, and aggregate characteristics.

- Water content: As the water content rises, the concrete becomes more fluid and offers more lubrication. This contributes to making the concrete more workable. The final option for improving the concrete’s workability should be to add more water, since this would negatively impact the material’s strength. In order to maintain the same water-to-cement ratio and, thus, the same level of concrete strength, more cement must be supplied in addition to additional water.

- Aggregate size: Larger particles have a lower surface area; therefore, less water is needed to lubricate the surface and lower friction. Large-sized aggregate makes concrete more workable; hence, this is the case (of course, within certain restrictions).

- Mix ratios: The ratio of cement to aggregate determines how rich or lean the concrete is. A greater ratio of cement to aggregate makes the concrete thinner. Less paste is available to lubricate the aggregate in lean concrete, but more paste is available in rich concrete with a low a/c ratio, improving the mix’s cohesiveness and workability.

- Aggregate shape: Compared to angular or flaky aggregates, rounded aggregates have a much smaller surface area and fewer voids, improving their ability to overcome frictional resistance. Furthermore, concrete has highly sharp particles that are flaky and angular.

- Aggregate surface texture: Aggregates with glossy or smooth textures have a smaller surface area than those with rough textures. Better workability results from using less water to provide the desired lubricating effect.

- Grading of aggregates: A well-graded aggregate has the fewest voids in a given volume. However, due to the glossy textured aggregate’s poor interlocking action, its usage is often prohibited in high-strength concrete. Improved workability will result from fewer voids and better aggregate grading.

- Utilising admixtures : The main element influencing concrete’s workability is the use of admixtures. The concrete becomes much more workable when plasticizers and super-plasticizers are used. The workability is increased by the production of air bubbles by air entraining agents, which function as rollers between particles and improve movement.

- Temperature and time: In time, fresh concrete becomes more rigid. This is due to the fact that during mixing the concrete, part of the water is absorbed by the aggregates and some evaporates. As a result, concrete becomes less workable with time. We refer to this gradual decrease of workability as “slump loss.” It is remarkable how temperature affects concrete’s workability. The combination becomes less workable as the temperature rises.

Types of Concrete Workability:

There are three categories of concrete workability:

- Unworkable Concrete

- Medium Workable Concrete

- Extremely Workable Concrete

1. Unworkable Concrete or Hard Concrete

- Another term for unworkable concrete is harsh concrete. Extremely little water is present in this concrete. Hand-mixing this kind of concrete is challenging.

- This kind of concrete has a high aggregate segregation rate because the cement paste is not sufficiently lubricated to stick to the particles.

- Concrete compaction requires a lot of labor, and maintaining the homogeneity of the mix is extremely difficult. A ratio of less than 0.4 exists between the water and cement in such concrete.

2. Medium Workable Concrete

- This kind of concrete workability is used in most construction projects. There is not much loss of homogeneity or segregation when this concrete is mixed, moved, laid, and compacted.

- This form of workability is often used in any concrete construction with light reinforcement (the reinforcing spacing allows the concrete to be compacted adequately). The water-to-cement ratio for medium-workable concrete is 0.4 to 0.55.

3. Extremely Workable Concrete

- Highly workable concrete in construction is relatively easy to mix, transport, install, and compress. When proper concrete compaction cannot be achieved, this kind of concrete is used in bulk concrete.

- This kind of concrete is easily worked and settles fast. However, segregation and homogeneity loss are rather likely in this case. Generally, the coarse particles settle to the bottom as the concrete paste rises.

- When robust reinforcement is required and vibration of the concrete is not an option, this kind of concrete is employed. One very workable kind of concrete is self-compacting concrete. The ratio of water to cement in this concrete is more than 0.55.

- The workability of concrete varies depending on the kind of construction and the compaction method used. Concrete workability requirements for mass concrete footing construction, for example, can be the same as those for slab construction.

- The workability standards differ based on whether vibrators are used in construction or not. The same goes for little pieces of concrete that are used for workability; they are not appropriate for workability.

Assessments of workability and Workability Examinations

Test of slump

It is the most often used technique for determining how workable newly mixed concrete is. It may be carried out on location as well as in a lab. By looking at how the concrete slumps, one may determine how uniform the concrete is from batch to batch in terms of quality and workability. extremely damp or extremely dry concrete is not a good fit for it.

A 300 mm-high steel mold with a top diameter of 100 mm, a bottom diameter of 200 mm, and a height of 300 mm is utilized for the slump test. The largest size of aggregate in concrete that may be utilized to conduct a slump test is 38 mm, following Indian standard specification.

After the mold has been thoroughly cleansed and cleared of any surface moisture, three layers of concrete are added. Using a normal tamping rod (16 mm dia, 0.6 meter length), each layer is tamped 25 times. As soon as the concrete is filled, the cone is gradually raised and given time to settle. Slump is defined as the reduction in the height of the slumped concrete’s center, to the closest 5 mm.

The measured slump is a real slump if the concrete sinks uniformly all around. A shear slump is considered to have occurred and the test has to be redone if one half of the cone slips down an inclined plane. A too-wet mixture demonstrates how collapsible the droop is.

Test for compacting factors

Although it may also be utilized on site, this test is often conducted in a laboratory. Because it is not affected by the slump test, it is especially helpful for extremely poor workability concrete mixtures (or very dry concrete).

This test measures the degree of compaction attained by letting the concrete fall to a predetermined height with a specified amount of labour.

| Container | Top diameter (mm) | Bottom diameter (mm) | Height (mm) |

| Upper hopper | 254 | 127 | 279 |

| Lower hopper | 229 | 127 | 229 |

| Cylinder | 152 | 152 | 305 |

| Distance between bottom of upper hopper and top of lower hopper = 203 mm | |||

| Distance between bottom of lower hopper and top of cylinder = 203 mm | |||

In order to prevent compaction, the concrete is gently placed into the upper hopper. The lower hopper is covered with concrete when the bottom door is opened. When the bottom door of the lower hopper is opened again, concrete falls onto the cylinder. After using blades to remove excess concrete, the weight of the cylinder (known volume) is calculated to the nearest 10 grams. This weight is referred to as “weight of partially compacted concrete”. The same sample is forcefully pushed into the empty cylinder in order to accomplish total compaction. The cylinder is weighed to the nearest 10 grams. This weight is referred to as “weight of fully compacted concrete”.

The compacting factor = (Weight of partially compacted concrete) / (Weight of totally compacted concrete).

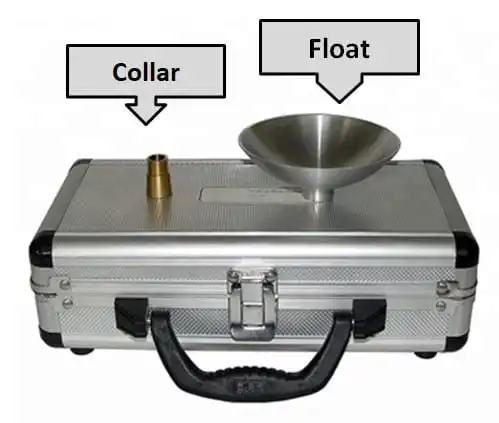

Vee-Bee analysis

The Vee-Bee test is a helpful laboratory test for stiff concrete mixes with low to extremely poor workability. It consists of a normal iron rod, a sheet of metal cone, a vibrating table, and a metal pot.

The test, which is the same as the one previously described, is performed by inserting the slump cone into the cylindrical pot composed of sheet metal. After that, a stopwatch is used to record the time and the vibration is turned on. Once the conical shape disappears, the length of time it takes for the concrete to become cylindrical is observed. This recorded time is called Vee-Bee seconds, or Vee-Bee degree.

| Workability of concrete (comparison of Slump test, Compacting Factor Test and Vee-Bee Test) | ||||

| Degree of workability | Slump (mm) | Compacting factor | Vee-Bee Test(seconds) | Suitability |

| Very low | 0 – 25 | 0.78 | 20 – 10 | · Roads where mechanical vibrators are used. |

| Low | 25 – 50 | 0.85 | 10 – 5 | · Roads where compaction is done manually.· Mass concrete foundations without vibration.· Lightly reinforced sections with vibration. |

| Medium | 25 – 100 | 0.92 | 5 – 2 | · Manually compacted flat slabs.· Manually compacted normal reinforced concrete.· Heavily reinforced sections with vibration. |

| High | 100 – 175 | 0.95 | 2 – 0 | · Sections with congested reinforcement without vibration. |

Flow Test

This is a laboratory test. It offers a gauge for the concrete’s cohesiveness, uniformity, and sensitivity to segregation. The measured spread of flow of the concrete is connected with workability. For this test, flowing concrete treated with superplasticizing admixtures is the ideal kind of concrete to employ.

The Test of Kelly Ball

This is a simple field test that calculates the depression that a 15 cm diameter, 13.6 kg weight metal hemisphere generates when it is placed freely on newly built concrete. It is faster and provides a more accurate workability rating than the slump test. But a lot of tangible work has to be done.