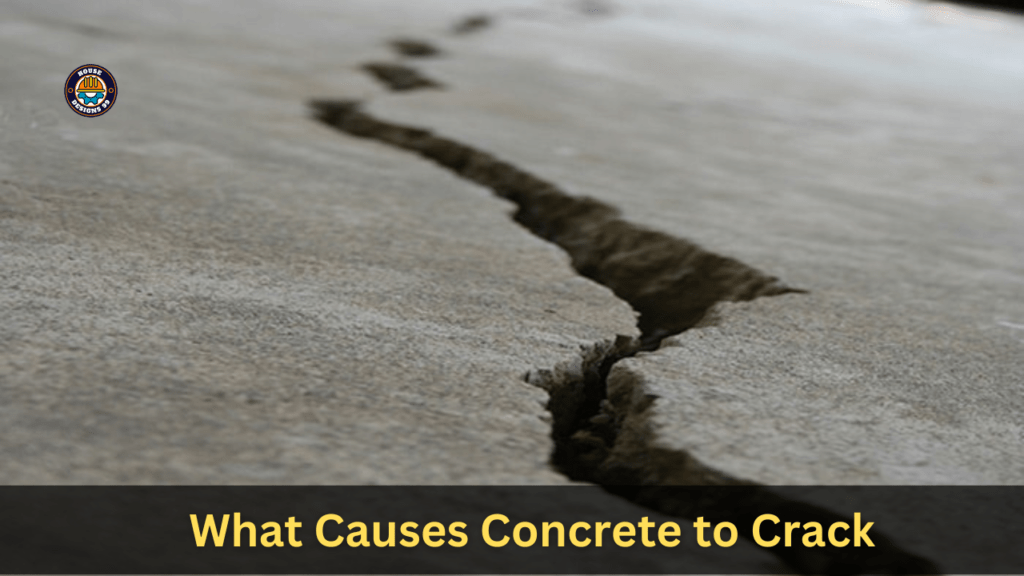

Why is concrete so in demand?

Crazing concrete is characterised by a hexagonal pattern that forms on the surface of the concrete and resembles a spider web. It is sometimes referred to as spider cracking or map-pattern cracking.

Concrete construction often experiences the issue of cracking. In actuality, it is quite uncommon to see a concrete surface devoid of cracks.

An improper mixture composition is one of the numerous factors that might cause premature or early cracking of the concrete surface. inadequate solar exposure, inadequate concrete hydration, and the use of unsuitable curing conditions or methods.

If the purpose of the concrete is to create crazing, this normally happens a week after the concrete mixture settles.

If neglected, these fissures enlarge over time and need treatment. Usually, the apparent fractures range in depth from 2 to 3 mm. Note that while the structure’s strength or durability are unaffected by cracking concrete, the visible fissures might give the appearance of severe damage.

In any event, if these fissures are not sealed up for an extended period of time, they could grow into larger fissures that allow moisture or water to get deeply into the structure and cause metal to corrode.

Although the visible effects of crazing concrete may be unsightly and the fissures may harbour dust or debris, the structure is not seriously affected by crazing.

The formation of a network of tiny, random fractures on the surface of concrete due to surface layer shrinkage is known as crazing. Drying shrinkage cracks and plastic shrinkage cracks are two other cracks that resemble craze cracking. Concrete cracks due to plastic shrinkage while it is still plastic.

These fissures are broader and deeper. They are also brought on by drying, when surface-level moisture evaporates. The second kind of cracks are called drying shrinkage cracks, and they usually appear after a concrete slab has solidified. The primary cause of it is the actual loss of water in the concrete mixture.

Reasons for Concrete Cracks

Concrete crazing may result from a number of factors. Both exposed surfaces and surfaces in close proximity to the formwork are susceptible to crazing. The primary cause is surface shrinking brought on by any natural, man-made, or environmental condition.

Improper Curing

When concrete is improperly cured and allowed to dry, the necessary quantity of water is not delivered to the concrete, causing the water to evaporate quickly from its surface. The concrete has dried out and is now absorbing more water. thus leading to the concrete’s crazing surface.

When concrete is placed in places with quick airflow, low humidity, direct sunlight, and unevenly distributed water on the surface, certain circumstances arise. The majority of the time, it happens as a result of the workers’ irresponsibility on that job.

A higher ratio of water to cement

Excessive water consumption might also result in crazing. A thin layer of water is formed at the surface by the extra water that was added to the concrete.

Subsequently, the extra water dries out and eventually causes the concrete to crack. A crucial responsibility is ensuring that the proper quantity of water is added to the concrete mix mixture.

Untrained Labour Force

Concrete that cracks is also a result of masons’ poor craftsmanship. The cement may sometimes come to the surface when a trowel is used to quickly settle the concrete.

Thus, there is water leaking. Cracks on the surface are also a result of this little mistake.

Finishing with Dry Cement

in order to get superior completion. A common practise among craftsmen is to dust the slightly wet concrete surface with dry cement, which accelerates the drying process and promotes the formation of fractures.

Intolerable Vibrations

Increasing vibrations during the concrete’s sinking process cause the cement slurry to rise to the top, leaving gravel and metal at the bottom.

Concrete that has cracked from the top dries out due to the cement. A common feature of modern concrete mixture vibrators is the ability to adjust the RPM (rotation per minute) to counteract concrete crazing.

Modern tools have greatly assisted in preventing crazing on the surface of concrete, which was formerly very likely to occur when physical labour was used to set the concrete rather than using electric vibrators.

Distillation

Concrete interacts with carbon dioxide in the air or carbon monoxide emitted by equipment or cars when the area is not sufficiently ventilated and the concrete is allowed to cure.

As soon as the concrete begins to settle, it causes the surface layer to shrink, resulting in fissures. This chemical reaction often occurs in messy, crowded, poorly ventilated environments.

Other factors include using excessively rich or wet mortar during construction and failing to properly cure the mortar. This might result in shrinkage. Crazing concrete also occurs when too fine sand is utilised and rendering or plastering is completed after a protracted period of time following concrete casting.

Preventing Concrete Cracking

Preventing concrete from cracking is important, as, as we all know, prevention is always preferable to treatment. Below, a variety of strategies for preventing cracking are covered. Don’t forget to look at them.

Concrete must be properly cured in order to avoid cracking. Simply put, curing is the process of providing an adequate level of moisture and warmth.

to the concrete in order to facilitate the hydration process and provide a smooth outcome. To get outcomes free of cracks, this has to be done.

Attempt to keep the surface moist most of the time by either adding only the appropriate quantity of water or by wearing or utilising damp clothing to trap the moisture. A sufficient water supply for two to three days is enough to keep the concrete from breaking.

It is recommended that the surface of the concrete that has been allowed to dry out never be covered with fine sand or dry cement. Since little moisture can adequately bond the cement particles, all of the moisture is absorbed by the dry cement or sand, and this moisture loss progressively takes the form of fractures.

In order to lessen the possibility of drying shrinkage, normal or expansion joints are often installed in the pavement or floors of building sites. Furthermore, this is not a perfect remedy.

Limiting the overuse of trowels Additionally, stay away from steel floats as much as you can. Try using air-entrained concrete with a modest slump. Air entertainment will lessen the chance of crazing and slow the rate of bleeding in concrete.

A stable surface with enough water content turns out to be a useful way to prevent cracks. When completing the concrete’s settling process, never hurry. It is advisable to give concrete a little more time to settle.

Repeated troweling is not necessary to achieve homogenous concrete surfaces free from cracks. Only the trowel should be used gently when the water has vanished from the surface.

One of the most frequent errors that is seen is when concrete is mixed with too much water in an attempt to improve uniformity, but the result is a slurry of concrete. Do not add too much water to the concrete mixture in order to prevent this.

Concrete Cracking Treatment

One of the greatest practises is to evenly glaze the concrete’s surface to get rid of or lessen the chance of surface cracking. When epoxy and silica sand are applied over concrete slabs, the result is a smooth, unbroken look.

In fact, this improves the colour and alters the surface’s appearance. Furthermore, any resurfacing product may be used to subsequently remove the excess surface.

Polishing the surface where apparent fractures exist is another highly helpful and practical therapy. Polishing finally removes the fractures, which are typically just 2-3 mm deep, by grinding the higher surface layer where the cracking pattern occurs.

Additionally, curing monomolecular chemicals may be applied to the surface to help stop concrete from cracking and to slow down the quick evaporation of moisture from the cement.

Grout may also aid in filling up those little gaps if cracking is not as noticeable. In summary, as we have covered in this essay, crazing concrete is a fairly frequent phenomenon that relies on a variety of circumstances.

Since cracks do not deteriorate over time, they are often left untreated. However, there are a number of techniques to stop the cracking, and the above highlights the importance of treating it properly. I hope you found this essay useful!