In this comprehensive guide, we will explore the Flash and Fire Point Test of Bitumen. Learn about the procedure, results, and important insights for this critical test used in the evaluation of bitumen properties.

Introduction

Bitumen, a vital component of road construction and waterproofing materials, is a highly viscous and sticky substance derived from petroleum. As with any material used in construction, it is essential to assess its behavior under different conditions to ensure safety and performance. The Flash and Fire Point Test is one such evaluation method that helps determine the temperature at which bitumen releases flammable vapors (Flash Point) and the temperature at which it sustains a fire (Fire Point).

In this article, we will delve into the detailed procedure and results of the Flash and Fire Point Test for Bitumen. We will provide expert insights, authoritative information, and valuable personal experiences to help you understand the significance of this test in assessing bitumen properties effectively.

The Importance of Flash and Fire Point Test of Bitumen

The Flash and Fire Point Test is of paramount importance in the construction industry. It helps engineers and researchers understand the safety aspects associated with bitumen. Here’s why this test is crucial:

- Safety Compliance: The Flash and Fire Point Test ensures that bitumen used in construction meets safety standards. It helps identify potential hazards related to its flammability, which is vital in preventing accidents during transportation, storage, and application.

- Performance Assessment: Bitumen’s ability to resist fire and high temperatures is essential for its performance as a road binder. This test provides critical data to optimize the formulation of bitumen and ensure its long-lasting performance in varying climatic conditions.

- Quality Control: By performing this test, manufacturers can validate the quality of their bitumen products. Consistent and accurate Flash and Fire Point results are indicators of a well-controlled production process.

The Flash and Fire Point Test Procedure

The Flash and Fire Point Test is conducted using specialized equipment, such as a Cleveland Open-Cup apparatus. Here’s a step-by-step guide to the procedure:

1. Sample Collection

The first step involves collecting a representative sample of bitumen. This sample should accurately reflect the properties of the entire batch or lot. Care should be taken to avoid any contamination during the collection process.

2. Apparatus Setup

The Cleveland Open-Cup apparatus is the most commonly used equipment for this test. The apparatus consists of a cup to hold the bitumen sample and a heating mechanism that gradually raises the temperature.

3. Test Initialization

A small portion of the collected sample is placed in the cup of the apparatus. The cup is then positioned in the heating device.

4. Temperature Increase

The heating mechanism is activated, and the temperature is gradually increased at a specified rate (usually 5°C per minute). Throughout this process, a flame is passed over the surface of the sample.

5. Observation

The test operator closely observes the sample for any signs of ignition, such as a flash of light or a sudden flame. The temperature at which the flash occurs is noted and recorded as the Flash Point.

6. Continuation of the Test

If a flash occurs, the test is continued, and the temperature is further increased until a steady flame is observed on the surface of the sample.

7. Determination of Fire Point

The temperature at which the steady flame sustains is recorded as the Fire Point.

8. Repeat Tests

For accurate results, multiple tests are conducted using different samples from the same batch, and an average value for both Flash and Fire Points is calculated.

Results and Interpretation

The results of the Flash and Fire Point Test are critical in understanding bitumen properties. Here’s how to interpret the outcomes:

- Flash Point: The Flash Point is the lowest temperature at which bitumen releases flammable vapors but does not sustain a flame. A higher Flash Point indicates that the bitumen is less likely to catch fire during handling and application.

- Fire Point: The Fire Point is the temperature at which bitumen sustains a steady flame. It is always higher than the Flash Point. The Fire Point is essential to assess the fire hazard associated with bitumen in case of accidents or mishandling.

- Safety Margin: The difference between the Flash and Fire Points provides a safety margin. A larger safety margin indicates a lower risk of accidental fires during storage and application

Aim:

The purpose of this study was to determine the flash point and fire point of asphaltic bitumen, fluxed native asphalt, blown type bitumen, and cutback bitumen.

The flash and fire point determination using Pensky-Martin’s Closed Cup tester is discussed in this section.

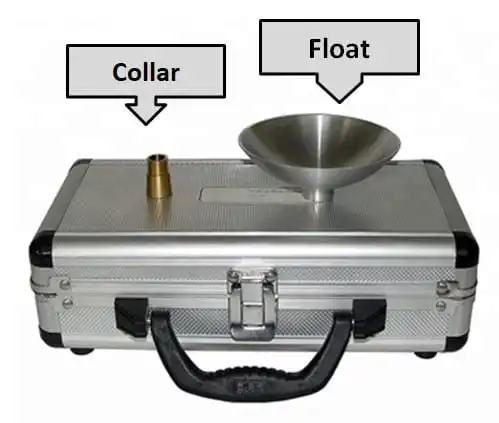

[The Cleveland Open Cup Apparatus is often used to evaluate the flash and fire point of a bituminous material.]

The Importance of Bitumen Flash and Fire Point Testing:

One of the most critical bitumen tests to do before road construction is the flash and fire point test.

The flash and fire point of a substance is the temperature at which it is likely to catch fire.

The temperature at which the bituminous material’s vapour catches fire or burns for a few seconds varies depending on the kind and grade of bitumen binder.

Because bituminous materials are mostly hydrocarbons, they emit a variety of volatile compounds at high temperatures. With a flash, these ejected volatile chemicals catch fire. And this may be dangerous.

Bitumen is heated before being used as a bitumen binder for road surfaces.

When working with hot bitumen during procedures such as heating, mixing, or application, the temperature should be maintained considerably below the flash and fire point critical temperatures.

Important Terms in Bitumen Flash and Fire Point Testing:

The flash point is the lowest temperature at which the vapour of bituminous substance catches fire in a flash form under certain circumstances.

The fire point is the lowest temperature at which the binder material ignites for at least 5 seconds under specified circumstances.

Apparatus:

The following equipment is necessary for conducting bituminous flash and fire point tests:

- Pensky Martens Tester: This is a bitumen flash and fire point testing unit. The following sections detail the many components of this apparatus:

- Closed Cup Tester: Made of brass, it has an internal diameter that is slightly bigger than the filling mark. Above the flange, the exterior surface of the cup is tapered. The flange also features facilities for accepting the cup’s lid and the cup itself when it is stored in the burner. A handle is also permanently attached to the cup flange.

- The top edge wall thickness must be at least 1 mm.

- Flange width = about 12 mm

- 3mm flange thickness

- Open Cup Tester: In this tester, the cup’s lid is replaced with a clip that encircles the cup’s top rim. It also has a test flame and a thermometer.

A lid has the following components:

- Stirring device: It is a vertical shaft located in the centre of the cup. There are two brass propellers on it. A collar holds the propeller blades. In a close cup test, the stirrer is mechanically manipulated. A hand-operated stirrer is required for testing cutback bitumen in a tight cup.

The following are the dimensions of different sections of the stirring device:

Vertical steel shaft diameter = 2.5-3 mm

Propeller blade width = 8 mm at roughly 45 degree angle

The smaller propeller’s overall diameter is 20 mm.

The bigger propeller’s overall diameter is 32-44 mm.

Propeller blade thickness = 1.2-2 mm

10 mm horizontal and vertical collar dimensions

10 mm is the distance between the plane of the propeller’s centre and the rim of the cup.

- Cover proper: The actual cover is made of brass. Its rim extends nearly to the cup’s flange and fits snugly around the outside of the cup. The cover has a correct locating device that interacts with the matching locating device on the cup’s flange.

The thickness of the cover is between 0.8 and 2 mm measured from just inside the rim.

[In open cup tests, a clip that encircles the top rim of the cup and includes a facility for holding the thermometer and test flame is used instead of a cover.]

The cover has four apertures, which are as follows:

Opening A is the area produced by the intersecting lengths of two radii and the arcs of two concentric circles.

Outer circle radius = 22.4-24.6 mm

Inner circle radius = 13.5-14.2 mm

Arc of the outer circular chord = 12.7-13.7 mm

Openings B and C have the same size. Their overall shape is similar to opening A, although they have around half the angular width.

Outer arc chord =4.8-5.6 mm

The sum of these openings’ areas equals 75-100% of the size of Opening A.

The angles formed by radii drawn across their centres are 135-140°.

Opening D: This is a divided tube that aids in gripping the thermometer. Its height should be such that when a standard thermometer is in place, the bottom of the bulb is 35.6-40.6 mm below the lip of the cup.

20 mm is the distance between the centre of the aperture and the centre of the lid.

10-15° angle of the opening to the perpendicular

- The shutter is constructed of brass and is affixed to the lid. It acts on the plane of the lid’s top surface. Its form and positioning are such that it revolves on the horizontal axis of the lid’s centre. When it is in an extreme position, the lid’s apertures A, B, and C are entirely closed. When it is moved to the other extreme, the lid’s apertures A, B, and C are entirely opened.

- Flame exposure device: It features a 0.7-.8 mm diameter aperture at the tip. When the shutter is open, it also features an operational mechanism that depresses the tip. A pilot frame is also included, which aids in the automated relighting of the exposure flame. A 4 mm bead is also put on the lid to control the size of the test flame. The spring-type shutter working mechanism is designed to close holes A, B, and C while the shutter is at rest.

- A heating appliance with a temperature control:

- Thermometer: Its temperature range should be between -7 and +110 degrees Celsius, with a minimum count of 0.5 degrees Celsius.

- Additional devices used in flash and fire point tests include:

Ignition source apparatus

Air bathing

Materials:

Bituminous substance

Cleaning solution

Precaution:

To ensure reliable findings, the following measures should be followed while doing bituminous flash and fire point tests:

- The size of the test flame and the frequency with which it is applied must be followed, or else the top layer will be superheated.

- The blue flame that surrounds the test flame is not the same as the genuine flame.

- The solvent used to clean the device should be entirely eliminated.

- The cup’s and lid’s locating devices must be correctly engaged.

Bitumen Flash and Fire Point Test Procedure:

For evaluating the flash point of bitumen, two kinds of testers are available: closed cup testers and open cup testers. However, the fire point of bitumen can only be tested with an open cup tester.

Closed Cup Tester Determination of Flash Point:

The method for determining the flash point in a closed cup tester differs for cutback bitumen. Both procedures are detailed below-

EXCEPT for cutback bitumen, the following rules apply to bituminous materials:

- Allow all pieces of the cup and its attachments to dry after properly cleaning them.

- Place the bitumen sample in a beaker and heat it to 75-100°C–just over its estimated softening point. Allow the bitumen to melt until it is totally transformed into a liquid.

- Fill the cup halfway with molten bitumen, up to the filling mark on the cup.

- With the aid of the lid, close the cup. Check that the cup and lid’s locating devices are correctly engaged.

- Place the cup on top of the burner.

- Insert a thermometer and set the test flame to the size of a 4 mm bead. Control the pace of heat delivery such that the temperature rises by 5-6 degrees Celsius each minute as measured by the thermometer.

- Turn the stirrer at a pace of 60 revolutions per minute.

- When the temperature reaches roughly 17 °C before the actual flash point, apply the first test flame. When the test flame is applied, stop stirring.

- Apply a test flame at each temperature reading up to 104 °C in 1 °C increments. When the temperature surpasses 104 °C, repeat the test at 2 °C intervals.

- Control the shutter and test flame burner in such a manner that the flame is decreased in 0.5 seconds for the device to apply the test flame. It is lowered for a second before being immediately raised to the higher position.

- Take note of the temperature at which a definite flash appears in the cup’s inside.

| Result for Flash and Fire Point Test of Bitumen | |

| Flash point | The temperature at which the first distinct flash is observed |

| Fire point | The temperature at which the material is ignited for at least 5 seconds |

| Flash point of the sample | The average flash point value of the 3 samples(The three values should not differ by ± 2 °C for the flash point below 104 °CThe three values should not differ by ± 5.5 °C for the flash point beyond 104 °C) |

| Fire point of the sample | The average of the fire point value of the 3 samples(The three values should not differ by ± 8 °C) |

For Reduced Bitumen:

- Heat the material to 17 degrees below the intended flash point. Bring the tester up to temperature as well.

- To remove the air, fill the area between the cup and the inside of the air bath with the same temperature.

- The preceding technique is then repeated. Except for the pace at which heat is applied. Control the pace of heat delivery such that the temperature rises by 1-1.5 degrees Celsius each minute as measured by the thermometer.

- Turn the stirrer at a rate of 70-80 revolutions per minute.

- The test flame is then applied, and the other steps are repeated except for the interval at which the test flame is applied. Instead of applying the test flame at 1 °C intervals, it is applied at every 0.5 °C rise in temperature.

Open Cup Tester Determination of Flash Point and Fire Point in Flash and Fire Point

- Clean and dry all of the parts of the cup and its accessories thoroughly. Ensure that all traces of the cleaning solvent are removed.

- Place the bitumen sample in a beaker and heat it to 75-100°C–just over its estimated softening point. Allow the bitumen to melt until it is totally transformed into a liquid.

- Fill the cup halfway with molten bitumen, up to the filling mark on the cup.

- Position the clip on the cup. Check that the cup and lid’s locating devices are correctly engaged.

- Insert a thermometer and set the test flame to the size of a 4 mm bead. Control the pace of heat delivery such that the temperature rises by 5-6 degrees Celsius each minute as measured by the thermometer.

- During heating, keep a close eye on the material’s surface.

- The steps are then repeated as in the closed cup tester, except that the stirrer is rotated manually rather than mechanically.

- Take note of the temperature at any point on the material’s surface where the first distinct flash appears. Take note of this temperature as the flash point.

- Continue heating beyond the flash point, using the test flame at 1 °C intervals.

- Take note of the temperature when the material ignites and burns for at least 5 seconds. Take note of this temperature as the fire point.

The entire practical is repeated twice more. The flash point and fire point of the given bitumen specimen are determined by the corresponding average value of the three tests.

Observation:

At a certain temperature, a flash can be seen when the test flame is applied. This temperature is recorded as the flash point.

The test flame is then applied once more. The fire occurs for at least 5 seconds at a certain temperature. This temperature is recorded as the fire point.

Table of observations:

(A sample observation table for flash and fire point test is drawn below)

| Readings | |||

| Trial 1 | Trial 2 | Trial 3 | |

| Flash Point in °C | |||

| Fire point (b)in °C | |||

Flash point of the sample = Average value of flash point of 1, 2, 3.

Fire point of the sample = Average value of fire point of 1, 2, 3.

Result:

The flash point and fire point values of the supplied bitumen specimen are the average of the flash point and fire point values obtained from the three tests.

For near cup testers, the flash point value should not deviate by more than 2 °C for temperatures less than or equal to 104 °C. When the temperature exceeds 104 °C, the tolerance value is raised to 5.5 °C.

For an open cup tester, the flash and fire point results should not deviate by more than 8 °C when tested three times.

The flash and fire point of a bitumen specimen are affected by its grade.

FAQs

What is the Flash and Fire Point Test of Bitumen?

The Flash and Fire Point Test of Bitumen is a critical evaluation method used to determine the temperature at which bitumen releases flammable vapors (Flash Point) and the temperature at which it sustains a fire (Fire Point). This test is essential for assessing the safety and performance of bitumen in construction and road paving.

How does the Flash and Fire Point Test work?

The test involves heating a small sample of bitumen in a Cleveland Open-Cup apparatus while gradually increasing the temperature. During this process, a flame is passed over the surface of the sample. The test operator closely observes the sample for any signs of ignition. The temperature at which the bitumen releases flammable vapors (Flash Point) and the temperature at which it sustains a steady flame (Fire Point) are recorded.

Why is the Flash and Fire Point Test important in construction?

The Flash and Fire Point Test is crucial for ensuring safety compliance in construction projects. It helps identify potential fire hazards associated with bitumen, making it easier to implement necessary safety measures during transportation, storage, and application. Additionally, the test provides valuable data to optimize the formulation of bitumen, ensuring its long-lasting performance in varying climatic conditions.

What are the applications of the Flash and Fire Point Test results?

The results of the Flash and Fire Point Test are used for quality control in the production of bitumen. Manufacturers can validate the quality of their products and maintain consistency in their production processes. Additionally, engineers and researchers use the test results to make informed decisions about the safe use of bitumen in construction projects, reducing the risk of accidents and ensuring the utmost safety for workers and the public.

Can the Flash and Fire Point Test results vary for different batches of bitumen?

Yes, the Flash and Fire Point Test results may vary slightly for different batches of bitumen due to variations in the manufacturing process and raw materials. It is essential to conduct multiple tests using different samples from the same batch and calculate average values for accurate results.

What precautions should be taken during the Flash and Fire Point Test?

During the test, it is crucial to follow safety protocols to prevent accidents. Adequate ventilation should be provided, and fire safety measures should be in place. Test operators must wear appropriate protective gear to ensure their safety while handling flammable materials.

Conclusion

The Flash and Fire Point Test is an indispensable tool in evaluating the safety and performance of bitumen used in construction projects. By understanding the Flash and Fire Points, engineers can make informed decisions regarding the storage, transportation, and application of bitumen, ensuring the utmost safety for workers and the public.

In this article, we explored the detailed procedure for conducting the Flash and Fire Point Test and highlighted its importance in quality control and safety compliance. By adhering to standardized testing procedures, we can harness the full potential of bitumen as a reliable and durable construction material.

Remember, always prioritize safety and quality in construction projects, and the Flash and Fire Point Test of Bitumen plays a vital role in achieving these goals.

============================================