Discover the difference between cement vs concrete in this comprehensive and informative article. Learn about various types of cement, how to make concrete, advantages of using concrete, and more. Gain insights from an expert in the field.

Introduction

In the world of construction and infrastructure, the terms “cement” and “concrete” are often used interchangeably, leading to confusion among many. However, it is essential to understand that cement and concrete are distinct materials, each playing a crucial role in the building process. In this article, we will delve into the differences between cement and concrete, explore the various types of cement available in the USA, Europe, and India, learn how to make concrete, and understand the advantages of using concrete in construction.

Difference Between Cement Vs Concrete

Before we delve into the specifics, let’s clarify the fundamental difference between cement and concrete. Cement is an essential binding agent used to hold together other materials, primarily aggregates, to form concrete. Concrete, on the other hand, is a mixture of cement, aggregates (such as sand, gravel, or crushed stone), water, and sometimes additives. The combination of these ingredients results in a durable, strong, and versatile building material suitable for various construction applications.

| Sr. No. | Cement | Concrete |

| 1. | Cement is manufactured by a chemical combination of calcium, silicon, aluminum, iron, and other ingredients. | It is a mixture of cement, sand, aggregate, and water to form a strong mass. |

| 2. | It is used as a bond agent in concrete, mortar. | Concrete is strong material used to cast structural components like columns, beams, and slabs, etc. |

| 3. | When water is added to cement it produces heat of hydration. | Cement within concrete produces heat to hydration which helps in gaining strength. |

| 4. | The strength of cement depends on the chemical composition of different ingredients used to make cement. | The strength of concrete depends on the water-cement ratio and concrete mix ratio of materials like cement, sand, aggregate, and water. |

| 5. | Cement manufacturing is a complex process only possible in manufacturing factories. | Concrete making is a simple process. It can be made on a construction site with decent skilled work. |

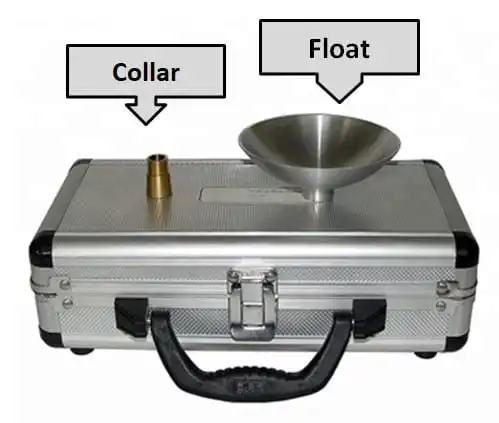

| 6. | Test of Cement: Fineness, Consistency, Initial and final cement time, soundness, specific gravity Test | Concrete Test: Compressive strength test, Slump test, Rebound hammer, Compaction factor test. |

What Is Cement?

Cement is a fine powder made from a combination of limestone, clay, and other minerals that are heated to a high temperature, then ground to a fine powder. The most commonly used cement is Portland cement, known for its superior quality and widespread usage in construction projects. Other types of cement, such as White Cement, Rapid Hardening Cement, and Sulphate Resisting Cement, offer specific properties suitable for various applications.

Types of Cement Available in USA

In the United States, several types of cement are available to cater to different construction needs. The following are the most common types:

- Portland Cement: Widely used for general construction purposes, it comes in different grades, such as Type I, II, III, IV, and V, each offering unique characteristics.

- White Cement: This type of cement is known for its aesthetic appeal and is primarily used in decorative applications and architectural designs.

- Masonry Cement: Designed specifically for use in masonry construction, it provides excellent workability and bond strength.

- Oil-Well Cement: Formulated to withstand high temperatures and pressures, it is used in drilling operations for oil and gas wells.

Types of Cement Available in Europe

Europe offers a diverse range of cement types, reflecting the continent’s rich architectural heritage and construction practices. Some prominent types include:

- Ordinary Portland Cement (OPC): Similar to Type I Portland cement, it is widely used in most construction projects.

- Rapid Hardening Cement: As the name suggests, this cement sets and hardens rapidly, making it suitable for time-sensitive projects.

- Low Heat Cement: Designed to generate less heat during hydration, it is useful in large concrete structures.

- Blast Furnace Cement: Made from a blend of granulated blast furnace slag and Portland cement, it offers enhanced durability and lower carbon footprint.

Types of Cement Available in India

India, being a diverse country with varied construction needs, offers a wide array of cement types. Some notable ones are:

- Ordinary Portland Cement (OPC): The most commonly used cement in India, available in different grades for various applications.

- Pozzolana Portland Cement (PPC): This type of cement contains pozzolanic materials like fly ash, enhancing its durability and reducing the carbon footprint.

- Portland Slag Cement (PSC): Combining slag from blast furnaces with OPC results in a cement with improved durability and lower energy consumption.

- White Cement: Used for decorative purposes, it adds an elegant touch to architectural designs.

What Is Concrete?

Concrete is a versatile and widely-used building material consisting of cement, aggregates, water, and sometimes admixtures. The combination of these ingredients creates a strong and durable material with a wide range of applications in the construction industry. Concrete can be tailored to meet specific project requirements, making it a popular choice for builders and engineers alike.

How to Make Concrete

The process of making concrete is relatively straightforward and follows these basic steps:

- Gathering Materials: Collect cement, aggregates (sand, gravel, or crushed stone), water, and any desired admixtures.

- Mixing: Combine the cement and aggregates in precise proportions in a concrete mixer. Gradually add water while mixing until a consistent and workable mixture is achieved.

- Transportation: Transfer the freshly mixed concrete to the construction site using a concrete truck.

- Placement: Pour the concrete into formwork or molds, ensuring it reaches all required areas.

- Curing: Allow the concrete to cure and gain strength over time by maintaining proper moisture levels.

- Finishing: Depending on the project, finishing techniques like smoothing, texturing, or polishing may be applied.

Types of Concrete

Concrete offers a variety of types, each tailored to specific applications and requirements. Some commonly used types include:

- Plain Concrete: Basic concrete without any reinforcement, used in non-load bearing structures.

- Reinforced Concrete: Incorporates steel bars or mesh to enhance strength and flexibility, commonly used in buildings and bridges.

- Stamped Concrete: Concrete with patterns or textures imprinted on its surface, providing an aesthetic appeal for driveways, patios, and walkways.

- Precast Concrete: Manufactured in controlled environments and then transported to the construction site, ensuring consistent quality and reducing on-site labor.

- Shotcrete: Also known as sprayed concrete, it is applied using a high-pressure hose, ideal for hard-to-reach areas and slope stabilization.

- High-Strength Concrete: Engineered to bear heavy loads and resist extreme forces, it is suitable for tall buildings and heavy infrastructure.

Advantages of Concrete

Concrete offers several advantages that make it a preferred choice for construction:

- Strength and Durability: Concrete structures can last for decades, even in harsh conditions, due to their exceptional strength and durability.

- Versatility: Concrete can be molded into various shapes and sizes, making it suitable for a wide range of applications.

- Fire Resistance: Concrete’s inherent properties make it highly resistant to fire, ensuring safety in buildings.

- Cost-Effective: The availability of raw materials and ease of production make concrete a cost-effective choice for construction.

- Sustainability: The use of locally-sourced materials and potential for recycling make concrete a sustainable building option.

- Low Maintenance: Concrete structures require minimal maintenance, reducing long-term upkeep costs.

Conclusion

Understanding the difference between cement and concrete is essential for anyone involved in construction or engineering. Cement serves as the binding agent that holds the components of concrete together, resulting in a versatile and durable building material with numerous applications. With a wide variety of cement types available in different regions, and the ability to create various types of concrete, builders and engineers have the flexibility to cater to specific project needs effectively.

Cement Vs Concrete

- Cement: The binding agent.

- Concrete: The final product.

============================================

FAQs:

Q: Is cement the same as concrete?

A: No, cement and concrete are different materials. Cement is a binding agent used to create concrete when mixed with aggregates and water.

Q: What are the types of cement available in the USA?

A: Some types of cement available in the USA include Portland Cement, White Cement, Masonry Cement, and Oil-Well Cement.

Q: How do I make concrete?

A: To make concrete, mix cement, aggregates, and water in the right proportions, then pour the mixture into the desired formwork and let it cure.

Q: What are the advantages of using concrete in construction?

A: Concrete offers strengths, durability, fire resistance, versatility, cost-effectiveness, and sustainability, making it a preferred choice in construction.

Q: Can concrete be used for decorative purposes?

A: Yes, concrete can be used decoratively through techniques like stamped concrete, which imprints patterns and textures on the surface.

Q: How long does concrete last?

A: Concrete structures can last for decades, with proper maintenance, even in challenging environments.