The float test of bitumen is a vital quality control measure in road construction. Learn about the apparatus used, the step-by-step procedure, and how to interpret the results of this test.

Introduction

Bitumen is a crucial component in road construction, providing the binding material that holds aggregates together. To ensure the quality and suitability of bitumen for road applications, various tests are conducted, one of which is the float test. The float test determines the purity of bitumen by measuring its specific gravity. In this article, we will explore the apparatus used, the step-by-step procedure, and how to interpret the results of the float test of bitumen.

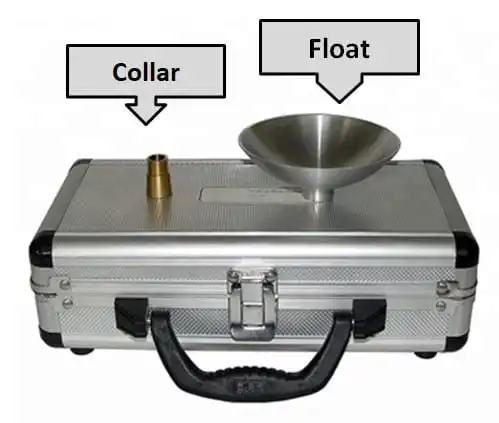

Apparatus for Float Test of Bitumen

The float test requires specific apparatus to accurately determine the specific gravity of bitumen. Here are the essential items needed for the test:

1. Graduated Cylinder

A graduated cylinder with precise volume markings is used to measure the volume of bitumen.

2. Water Bath

A water bath is essential to maintain a constant temperature during the test, ensuring consistent results.

3. Thermometer

A thermometer is used to monitor and control the temperature of the water bath.

4. Bitumen Sample

A representative bitumen sample is required for the test. It should be free from any impurities or contaminants.

5. Weighing Scale

A weighing scale with high accuracy is used to measure the mass of the bitumen sample.

6. Water

Water is used in the test as a reference fluid to determine the specific gravity of bitumen.

Procedure for Float Test of Bitumen

Performing the float test requires following a specific step-by-step procedure to obtain accurate results:

1. Preparing the Bitumen Sample

Ensure that the bitumen sample is clean, free from any moisture, and at a stable temperature.

2. Weighing the Bitumen Sample

Using the weighing scale, measure the mass of the bitumen sample (M1) accurately.

3. Measuring the Water Level

Fill the graduated cylinder with a known volume of water, and record its initial level (V1).

4. Immerse the Bitumen Sample

Carefully immerse the bitumen sample in the water-filled graduated cylinder.

5. Recording the Final Water Level

After the bitumen sample settles, record the final water level (V2) in the graduated cylinder.

6. Calculating the Specific Gravity

Calculate the specific gravity of bitumen using the formula:

Where:

M1 = Mass of empty graduated cylinder

M2 = Mass of graduated cylinder with immersed bitumen sample

V1 = Initial water level

V2 = Final water level

Interpretation of Results

The float test provides valuable insights into the purity and quality of bitumen. The specific gravity of pure bitumen typically ranges between 0.97 to 1.02. If the specific gravity obtained from the test is within this range, it indicates that the bitumen is of good quality and suitable for road construction. However, a significant deviation from this range may suggest the presence of impurities or contaminants, requiring further investigation or purification before use.

FAQs

Q: What is the purpose of the float test for bitumen?

The float test determines the specific gravity of bitumen, which is crucial for assessing its purity and suitability for road construction.

Q: Why is specific gravity important in bitumen testing?

Specific gravity is essential in bitumen testing as it indicates the purity and potential performance of bitumen in road applications.

Q: Can the float test detect impurities in bitumen?

Yes, the float test can detect impurities in bitumen, as a significant deviation from the standard specific gravity range may suggest the presence of impurities.

Q: How can the float test results be used to improve bitumen quality?

The float test results can be used to identify impurities or inconsistencies in bitumen and guide necessary purification or adjustments to enhance its quality.

Q: What are the advantages of using the float test in road construction?

The float test provides a simple yet effective way to assess the quality of bitumen, ensuring that only pure and suitable bitumen is used in road construction, which contributes to the durability and longevity of roads.

Q: Can the float test be used for other materials besides bitumen?

The float test is primarily designed for bitumen testing due to its unique properties and importance in road construction. It may not yield accurate results for other materials.

Conclusion

The float test of bitumen is a vital quality control measure that ensures the purity and suitability of bitumen for road construction. By determining the specific gravity of bitumen, this test provides valuable insights into its potential performance and identifies the presence of impurities or contaminants. Performing the float test using the specified apparatus and following the step-by-step procedure is crucial to obtaining accurate results. Proper interpretation of the test outcomes helps builders and engineers make informed decisions, ultimately leading to the construction of durable and reliable roads.